METAL FABRICATION

Metal fabrication is the process of building machines or their parts and structures from different types of metals and alloys. The process usually includes cutting, machining, burning, welding, forming, and assembly to create the finished goods.

Metal fabrication projects include everything from hand railings to heavy-duty equipment and industrial machinery. Other sectors include architectural and structural metals, cutlery and hand tools, hardware, spring, wire, screw, nut, and bolt manufacturing. Stamping and engraving is the modern age metal fabrication domain.

The modern age has proved metal fabrication labs centralization a necessity with multiple processes under one roof that are often required to be done in parallel. A one-stop metal fabrication shop like Graphic Impression helps clients limit their need to work with multiple vendors to complete complicated projects.

How Is Metal Fabrication Performed?

The metal fabrication industry has various applications across multiple industries and consumer products. Standard raw materials used are metal sheets, metal rods, alloys, flat metal formed and expanded metal, sectional metal, fittings, castings, and welding wire.

The processes involved are as follows

- Reduction

- Shearing

- Punching

- Blanking

- Notching

- Shaping

- Folding

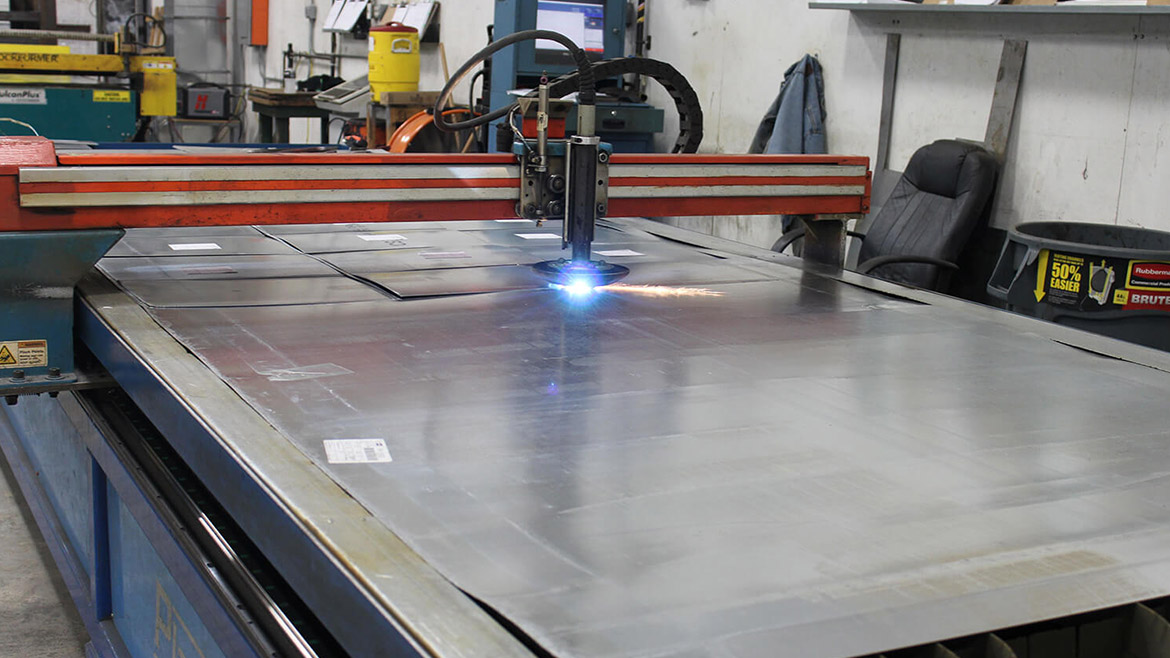

Metal fabrication has gone under lots of advancement with the passage of time and now all the processes have multiple ways and technologies like only cutting has so many different ways(Fiber Laser Cutting, Fiber Laser engraving, Plasma cutting, and flame Cutting) which give a different type of accuracy and they are available here at graphic Impression.